Product

Address: East of Floor 5, Building 3, Fubilan Dingfeng Hi tech Industrial Park, west of Songgang Avenue, Bao'an District, Shenzhen

Tel.: 0755-23496070 29174882

Fax: 0755-29170945

Email: youyan@szxinyutong.com

Website: www.szxinyutong.com

suzhou office

Room 1608, Unit 2, Building 42, Yongchang Jinghuayuan, Caohu Avenue, Xiangcheng District, Suzhou

Miss Yu: 13147004155

website: http://www.szxinyutong.com

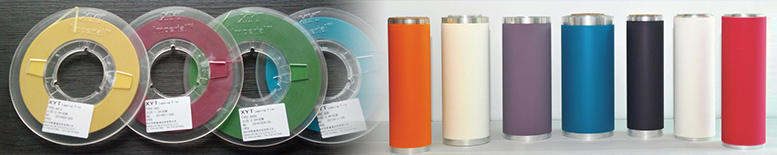

Cerium oxide polishing plate

Cerium oxide polishing plate

1. Product introduction: cerium oxide, full name: cerium dioxide. The Mohs hardness of cerium oxide is about 7. The strength of aggregates is different with different firing temperatures. Therefore, the same cerium oxide powder will have different hardness when using products from different manufacturers. Ceria silicate glass is widely used for polishing glass products due to its high chemical activity and comparable hardness.

The cerium oxide polishing plate of our company uses imported superfine cerium oxide powder as the basic raw material, which is evenly distributed in the adhesive. The precision coating technology introduced from Japan is applied to evenly coat it on the PET substrate, and finally it is dried and made of building materials. (Please feel free to contact us if you have other base material requirements or size requirements)

2. Product features:

★ Imported ultra precision ceria powder with good dispersibility

★ The bonding system adopts new polymer materials, which have good water resistance and alcohol resistance

★ Good polishing effect, high working efficiency and good performance

★ Long service life, small batch difference

★ Stable product quality

|

type |

Light green cerium oxide |

Off white cerium oxide |

|

Particle size (um) |

There are mainly two grades of 0.3-0.5um |

There are mainly two grades of 0.3-0.5um |

|

Grinding disc specification (mm) |

Wafer: Φ 70mm、 Φ 110mm、 Φ 127mm(5inch)、 Φ 203mm(8inch) Square piece: 114mm * 114mm, 152mm * 152mm (6inch) 228mm * 228mm (9inch) |

|

|

In addition to the above specifications and models, other specifications can be customized according to customer needs |

||

3. Scope of application:

★ This product is mainly used for the final polishing of optical fiber connectors. Note: After the ordinary ceramic insert is polished with this product, the end face effect is very good, but there are many optical fiber protrusions (negative values). Customers with high light requirements should use silicon oxide polishing pads

★ It can also be used for ultra precision processing of precision optical devices (for fast polishing of soft glass materials such as ZK and Lak or high-precision polishing of hard materials, such as glass disks, IC photomask, silicon chips, etc.)

★ During use, it is better to add grinding liquid (PGY-30 is recommended) to the cerium oxide polishing plate

★ Adjust the timing and pressure when polishing, and clean the polished surface with alcohol dust-free paper after each polishing

Address: East of Floor 5, Building 3, Fubilan Dingfeng Hi tech Industrial Park, west of Songgang Avenue, Bao'an District, Shenzhen

Tel.: 0755-23496070 0755-29174882 Fax: 0755-29170945 Website: www.szxinyutong.com

Diamond abrasive paper | ceria polishing sheet | silicon carbide abrasive paper | flannelette polishing sheet